How Warehouse Rack Design Supports Business Efficiency

Warehouse rack design plays a central role in how efficiently a business operates. The way storage is laid out affects travel distances, loading times, and how safely equipment can move around the building. When rack systems are designed around real operational needs, warehouses tend to run more smoothly and with fewer avoidable issues.

Designing Around Stock Movement

One of the first considerations in rack design is how stock enters, moves through, and leaves the warehouse. Inbound goods, picking routes, and despatch areas all influence where racking should be placed and how aisles are arranged. Poorly planned layouts often result in forklifts crossing paths, congestion near loading bays, and unnecessary handling.

Choosing Racking to Match Handling Equipment

The type of handling equipment used on site has a direct impact on rack configuration. Narrow aisle trucks, reach trucks, and counterbalance forklifts all require different aisle widths and beam heights. Designing racking without accounting for truck type can restrict access or reduce usable space. Clearances should allow safe operation without encouraging excessive speed or risky manoeuvres.

Storage Density Versus Accessibility

Not every warehouse needs maximum pallet density. Businesses that rely on fast picking and frequent stock rotation often benefit more from layouts that prioritise access. Others, such as operations storing seasonal or bulk goods, may accept slower access in return for increased capacity. Effective rack design balances these needs rather than focusing on a single metric.

The Role of Rack Design in Safety

Racking systems are structural installations and must be treated as such. Load ratings, beam deflection limits, and upright protection all form part of safe design. Adequate spacing reduces the likelihood of impacts, while clear signage helps operators understand safe working loads. Designing safety into the system reduces ongoing maintenance and repair costs.

Adapting to Business Growth

Many warehouses change over time as product ranges expand or distribution models shift. Rack systems that allow adjustments to beam levels or aisle layouts make it easier to respond to these changes without major disruption. This flexibility can be a deciding factor for businesses planning to grow within an existing building.

Making Better Use of Vertical Space

In many UK warehouses, vertical space is underused. Increasing rack height, where the building allows, can significantly improve storage capacity without expanding the footprint. This approach requires careful assessment of floor load limits and handling equipment, but it is often more cost effective than relocating or extending the site.

Working With a Planned Rack Layout

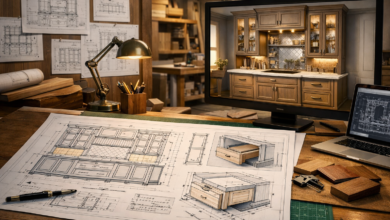

A structured approach to pallet racking design helps align storage systems with operational priorities. When layout, equipment, and stock profiles are considered together, businesses are better placed to improve efficiency while maintaining safe working conditions.

https://newsswift.co.uk/