Sodiceram: A Simple Guide to the New Sodium Ceramics

Sodiceram is a name you might see in articles, design pages, or product lines. Some pages talk about sodiceram as a new kind of ceramic material that uses sodium-based compounds. Other pages use the name for a tile or design collection. In this first half, I’ll explain the basic ideas. I will keep it simple and clear.

You will learn what sodiceram is, why sodium matters, and the main benefits people claim. I will use plain words and short sentences. If you like the tone, we will write the second half later with how it is made, tests, and real examples.

What is sodiceram?

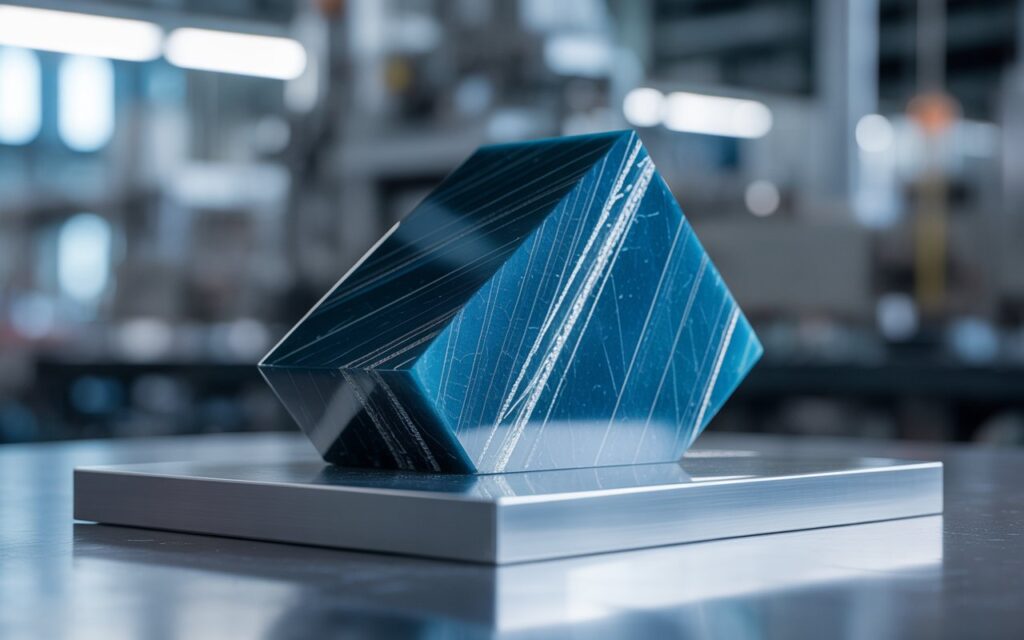

At its simplest, sodiceram refers to ceramics that use sodium compounds in their mix. In normal ceramics, clays and other minerals are heated until they partly melt and bind together. If sodium compounds are added, they act like a helper. They make parts of the clay soften and join at lower heat.

Some websites present sodiceram as a material idea. Other sites show sodiceram as a tile line for homes. That means the term can mean a recipe for clay, or it can mean a brand or style. Both ideas matter when you read about sodiceram.

Why sodium matters in ceramics

Sodium compounds are common in glass and ceramics. They act as a flux. Flux means an ingredient that helps melting happen at lower heat. Think of it like a helper that makes the work easier in the kiln. Because of this, sodiceram can often be fired at lower temperatures than traditional mixes.

Lower firing heat can mean less fuel and lower energy cost. That is one reason people find sodiceram interesting. Also, sodium can change the way glazes look and stick to the clay. That can help make smoother or brighter finishes. But the exact effect depends on the mix and on how the kiln is run.

Main benefits people talk about

Many sources list similar benefits for sodiceram. One is energy use. If a ceramic melts sooner, a maker may use less fuel. That can save money and lower emissions. A small tile shop can feel this in its bills.

Another benefit is finish and strength. Sodium can make a more glassy phase inside the ceramic. That can improve glaze fit and surface smoothness. Some write that sodiceram can have good strength and less cracking when the temperature changes. Designers also like the range of colors and textures possible with these mixes.

Where sodiceram can be used

Sodiceram shows up in many areas. In homes it can be tiles, wall accents, or decorative pieces. Some design pages focus on style. They show many colors and shapes that look modern and easy to match.

On the technical side, the concept may be used in special parts. People talk about heat-resistant pieces for cars, or small parts in electronics that need a stable surface. There are also mentions of medical or dental uses in some pages. For now, most public examples focus on tiles and design items for rooms.

Things to watch for

While the news about sodiceram can sound good, there are a few things to keep in mind. Adding sodium changes how the clay behaves in the kiln. That means makers must learn new steps. Handling some sodium compounds may need extra care in the workshop.

Also, not every sodiceram mix will behave the same. Some mixes may cost more. Some may work great for tiles but not for heavy load parts. The pages you gave me show the benefits and design ideas. They also note that production can be more complex. That means more testing is usually needed before a maker adopts it.

How sodiceram is made

Making sodiceram starts with clay, just like normal ceramics. But in this case, special sodium compounds are added to the mix. These sodium parts act like a helper during firing. They make the clay melt and stick together at lower heat.

The mix is then shaped into tiles, plates, or other forms. After shaping, the pieces are dried so they do not crack in the kiln. Then they are fired at the right temperature. Because of the sodium, the firing can be done at a lower heat compared to some other ceramic mixes. That can save energy.

After the firing, the surface can be glazed. Sodium helps glazes stick well and look smooth. The result is a strong, shiny, and sometimes very colorful finish. The exact steps can change based on what the product will be used for—tiles, art, or even technical parts.

Tests and quality checks

Like all ceramics, sodiceram pieces need to be tested. Makers check strength by pressing on samples until they break. They also check how the ceramic reacts when heated and cooled many times. This shows if it will crack or not.

Glaze tests are also common. Makers want to see if the glaze stays smooth, without bubbles or peeling. In some cases, sodiceram parts for electronics or medicine go through stricter tests. This ensures the material is safe and stable for long use.

By testing, makers can be sure that sodiceram tiles or parts will last for many years. Without these tests, buyers might not know if the product is really as good as promised.

How to choose sodiceram products

If you are thinking about buying sodiceram tiles or designs for your home, look at a few things. First, check the style and colors. One of the strong points of sodiceram is its wide range of looks. You can find smooth glossy tiles, matte textures, or even natural stone-like designs.

Second, ask about durability. Will the tiles resist scratches? Will they stay strong if hot water or sudden heat touches them? These are simple questions to ask a seller. It helps you pick a product that will last.

Third, think about where you want to use it. A living room wall may only need style. A kitchen or bathroom floor needs strength and easy cleaning. Sodiceram can be made for all these uses, but you need to match the product to the space.

Real-world uses today

Imagine a small café owner who wants to update the floor. Normal tiles look nice but may wear out fast. A sodiceram floor could give both style and strength. Because of the sodium mix, the tiles can handle heat and cleaning better.

Or think of a tech company that needs a ceramic part for electronics. They want it to resist heat while staying stable. A sodiceram part could be tested for that role. This shows how the same idea can work for both simple home design and complex tech.

In 2025, with more focus on saving energy, many makers are also looking for eco-friendly options. Because sodiceram can fire at lower heat, it may cut down energy use. This makes it more attractive for workshops and companies that care about the planet.

Final thoughts

Sodiceram is not just one thing. It can mean a special ceramic mix that uses sodium, or a brand that offers stylish tiles. Both ideas show why people are paying attention. It offers energy savings, strong finishes, and many design choices.

At the same time, it is important to remember that not every mix is the same. Some may cost more or need extra steps to make. Asking questions and looking for tested products is always a good idea.

For homes, sodiceram gives more style and choice. For industries, it can offer strong and heat-resistant parts. In both worlds, it feels like a material that fits the needs of 2025. If you are curious, it is worth looking closer at sodiceram and seeing if it is the right choice for your space or your work.